Parelia

Trilux

Parelia

Trilux

In 2017 Trilux launched the Repro-Light project to support the European lighting industry in moving towards a more sustainable and competitive future by investigating sustainability, the circular economy, the modularisation of luminaires and a smart production scheme.

In 2017 Trilux launched the Repro-Light project to support the European lighting industry in moving towards a more sustainable and competitive future by investigating sustainability, the circular economy, the modularisation of luminaires and a smart production scheme.

Researchers conducted a Life Cycle Assessment to quantify the environmental impact over a luminaire's life cycle.

It concluded that the most environmental burden was in the ‘use' phase. Trilux has since implemented modifications to product design and high-quality technology to reduce energy consumption and ADP elements significantly.

But the end-of-life still held many unanswered questions. Project SUMATRA was born to address these.

A luminaire's body is currently constructed from plastic or precious raw resources; so Trilux took the decision to learn from other industries and looked for more sustainable, biodegradable materials.

The surprising answer came from corn.

Polylactic acid (PLA) is a synthetic polymer-based on lactic acid and obtained in an environmentally friendly way from corn starch.

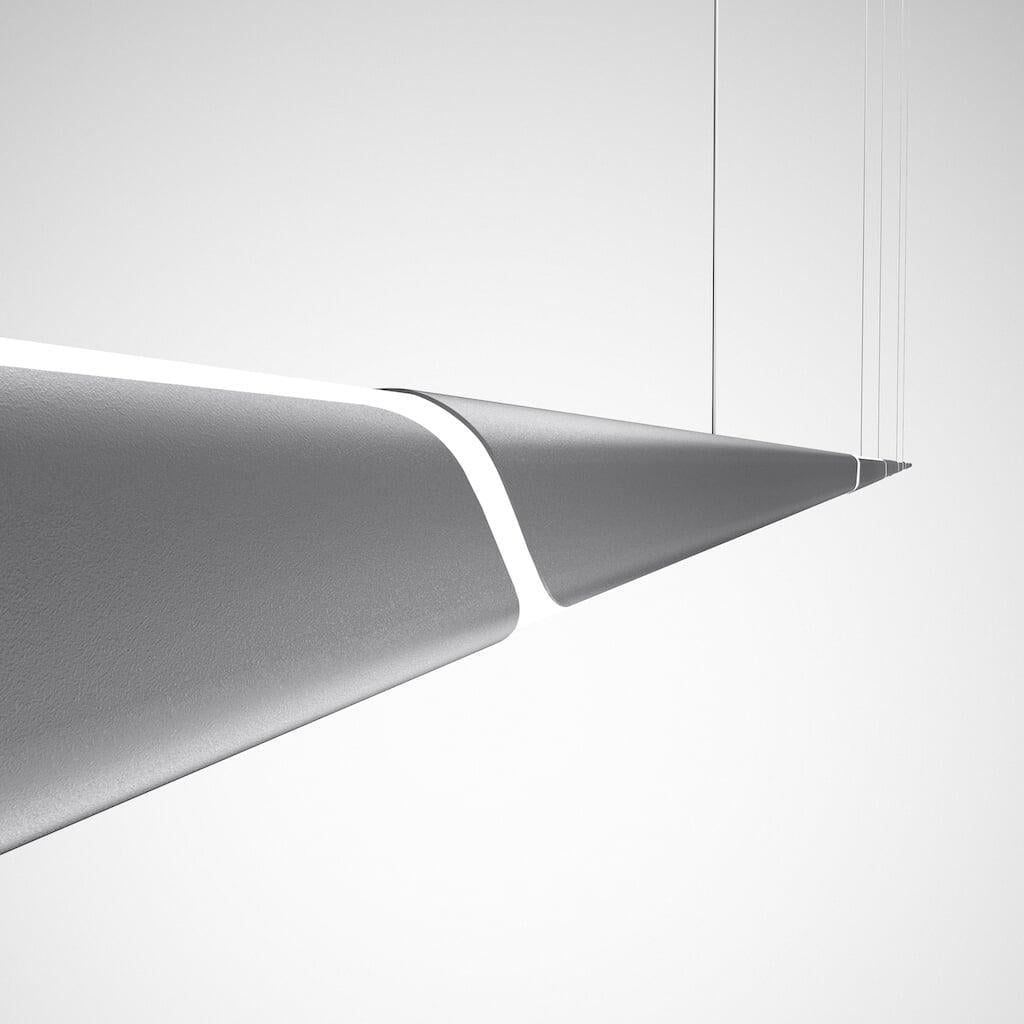

The biocompatible thermoplastic is suitable for producing the luminaire body using a 3-D printing process.

PLA products feature low moisture absorption and low flammability and high UV resistance, colour fastness, and bending strength.

Furthermore, the real advantage of PLA compared to conventional plastics is its biodegradability. Under industrial composting conditions, the material decomposes entirely in just a few months.

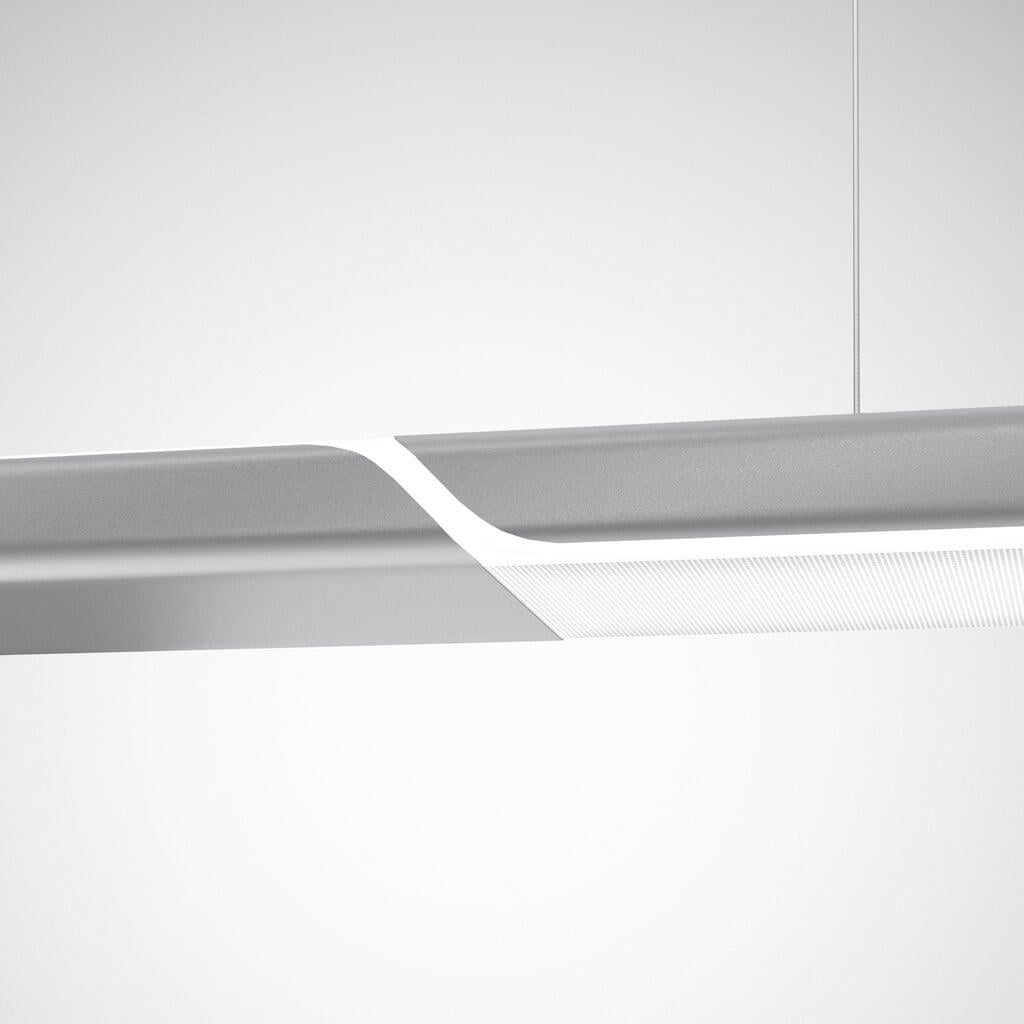

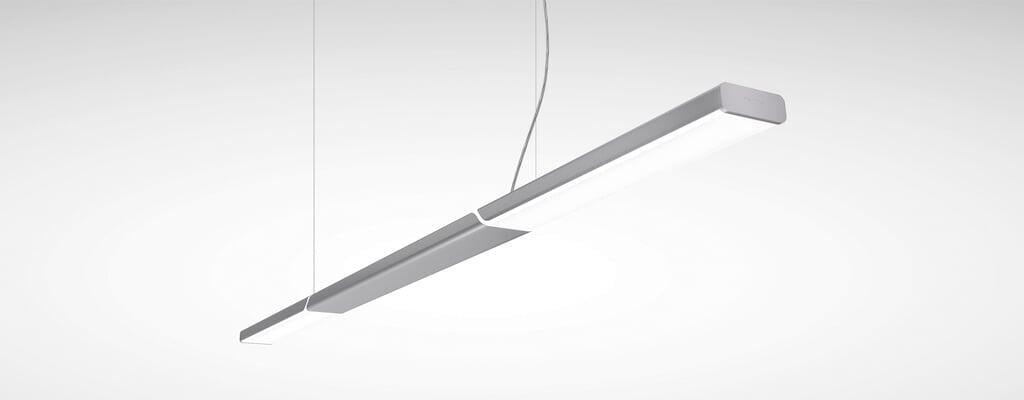

With GRAFT Architects, Trilux took its continuous light line, Parelia LED, and constructed the body from PLA.

Parelia is ideal for lighting modern offices parallel to the building axis, without reflected glare from the direct component.

Parelia LED was chosen as it has already received multiple awards for its outstanding design.

Thanks to its high-efficiency lighting technology and optics, it generates glare-free light with 80 per cent indirect light.

‘We deliberately selected a luminaire that poses a number of challenges for us in terms of design and construction,’ says Felix Götze, the industrial designer supervising the successful project at GRAFT. ‘This was based on the motto that ‘if it works here, it'll also work with all other luminaires’.

Aside from the housing, parts of the diffuser optic are also made from sustainable material.

The next steps, says Trilux, are to analyse the quality and performance of the PLA Parelia under real-world operating conditions.

The Build Back Better Awards judges called it ‘a big step forward in materials and manufacturing process’.